Kontakt

Vi ger personlig service från måndag till fredag, från 8:00 till 17:00. Via den här länken hittar du kontaktpersonen för din region.

Huvudkontor Wolfurt

+43 5574 6706-0

Varukorg {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artikel Ändra varukorg

Anmärkning

| Bild | Artikel | St | Enhetspris | Totalpris | Totalt pris inklusive rabatt | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Kunder

- Mould making

- Die making

- Maskin- och fixturbygge

- Konstruktörer

- Formsprutare

- Produkter

- Företag

- Karriär

- Service

Everything you need to know about gas springs – Part 4

Publicerad den: 02.02.2021

Tips for correct installation

In the fourth part of our series ‘Everything you need to know about gas springs’ we have summarised all information about installation and maintenance of gas springs for you. You will also find valuable tips on correct storage.

- If possible, always attach the gas spring to the die.

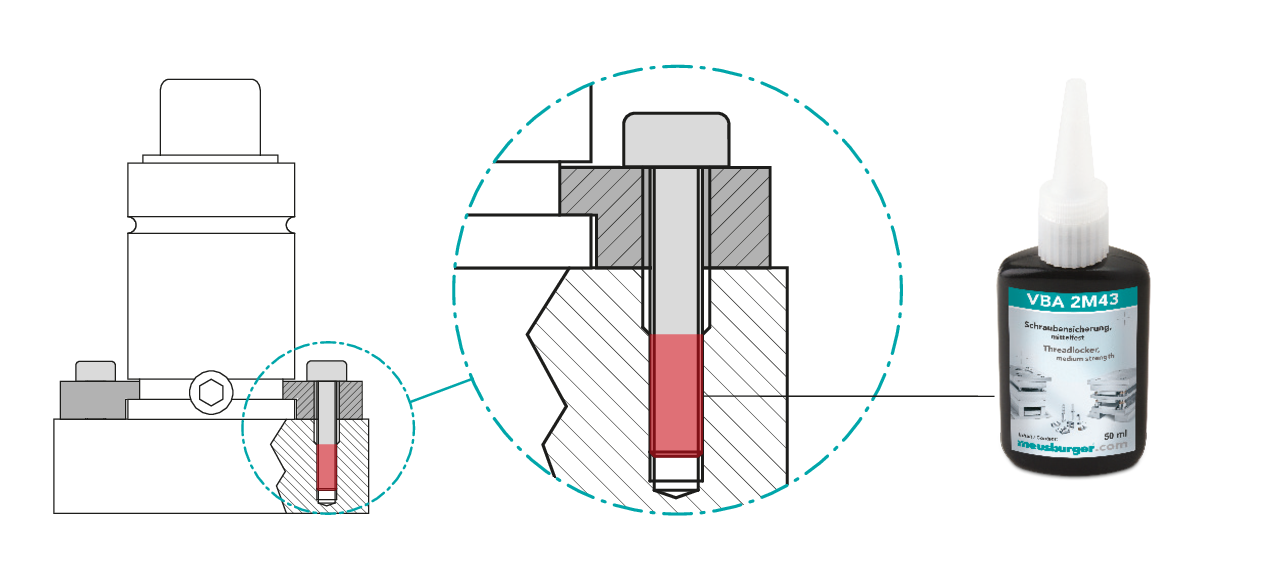

- Use a suitable threadlocker such as Meusburger VBA 2M43.

- Always observe the correct tightening torques as indicated.

- Check the condition of the gas springs and the fasteners after each modification on the die.

| Screw DIN EN ISO 12474:2011-01 class ≥ 8.8 | M5 | M6 | M8 | M10 | M12 | M16 |

|---|---|---|---|---|---|---|

| Tightening torque in Nm | 6 Nm | 10 Nm | 24 Nm | 50 Nm | 84 Nm | 205 Nm |

Dos and Don'ts

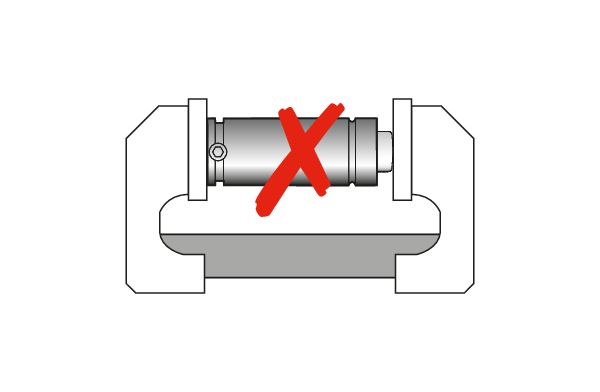

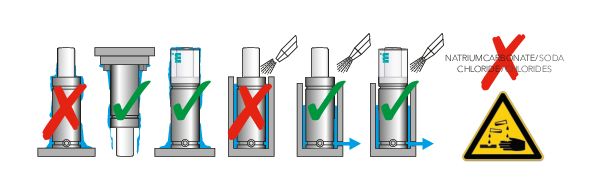

- Do not use a vice to check the cylinder’s force.

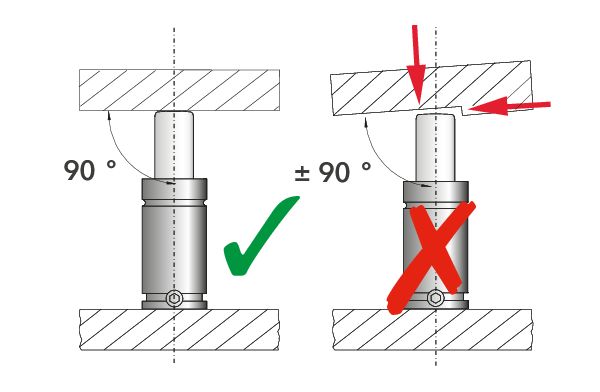

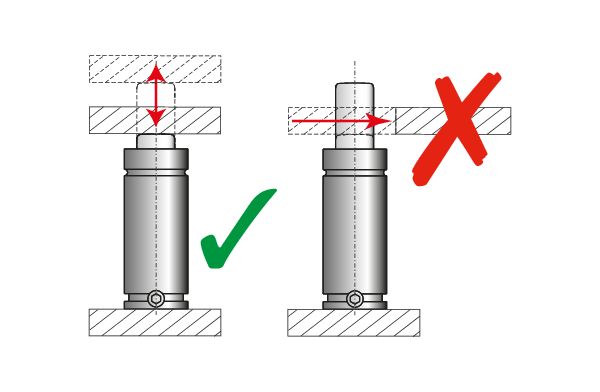

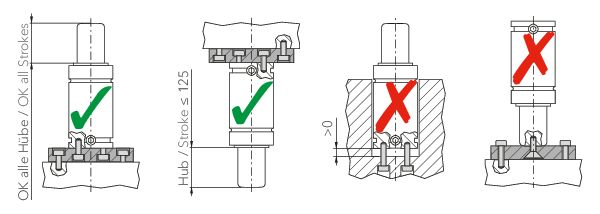

- Always position the gas spring perpendicular to the surface. Avoid any radial load during piston rod compression. Always apply pressure to the entire end surface of the piston rod. As much as possible, equalize the load in the die.

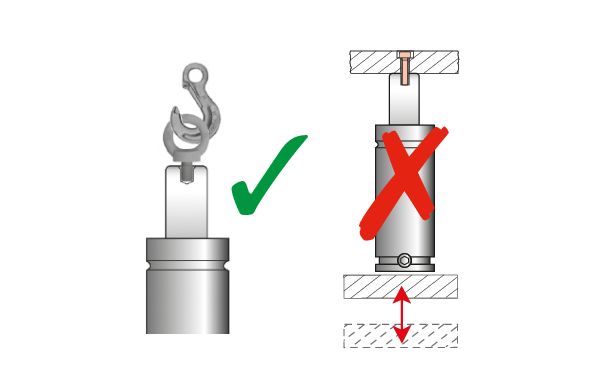

- Use the threaded hole on the piston rod for transport of the gas spring only. This hole may not be used to fix the gas spring.

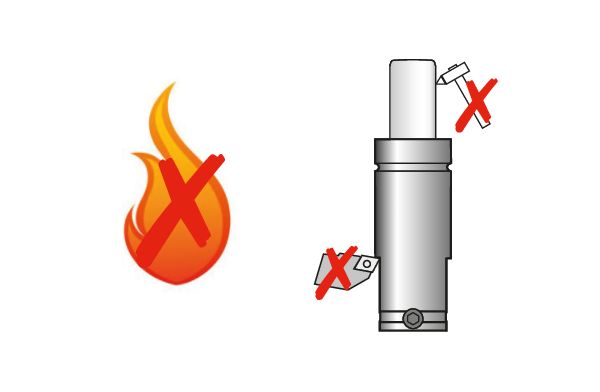

- Do not carry out any mechanical work on the cylinder or the piston rod.

- Any uncontrolled return stroke of the piston rod must be avoided as it may cause damages or mechanical failures on the cylinder or fixings.

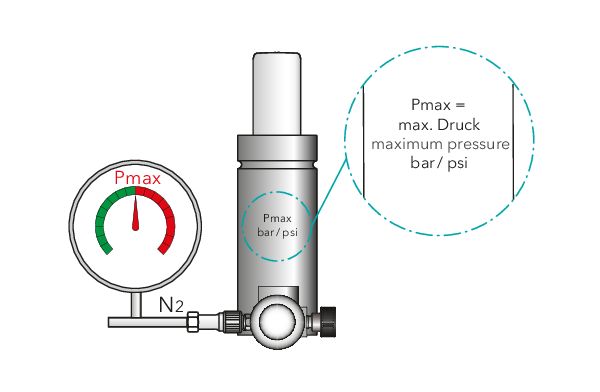

- Do not use any gas other than nitrogen N2 to fill the gas springs.

- Protect the gas springs from aggressive solids and fluids (such as sodium carbonates and chlorides). If they are used to clean the die, remove any residue from the gas springs.

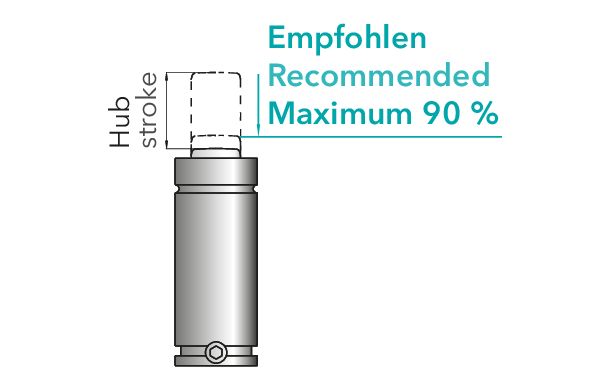

- It is recommended to have a stroke reserve of 10% of the nominal stroke length or 5 mm for strokes longer than 50 mm.

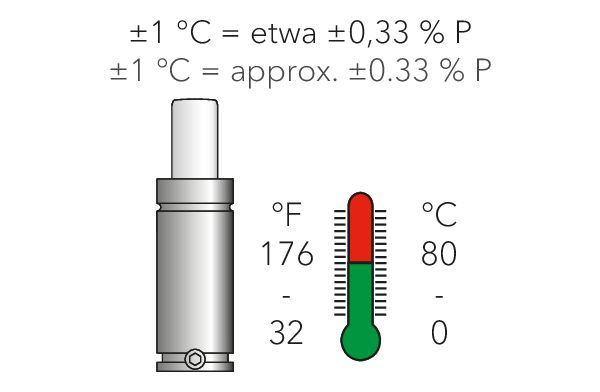

- Do not use the gas spring at temperatures higher than 80°C/176°F.

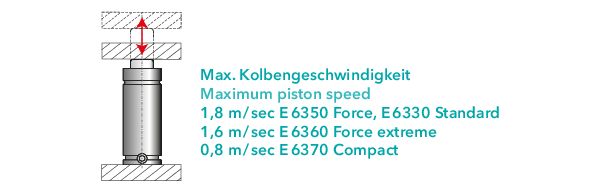

- Do not use the gas spring at a speed over 0.8 ÷ 1.8 m/sec.

- Do not charge cylinder over the maximum allowed charging pressure laser etched on the body.

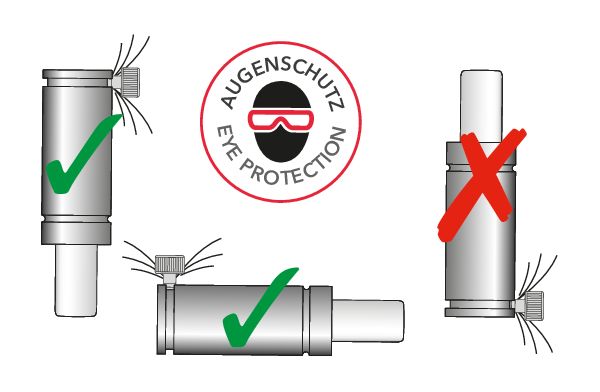

- During the discharging procedure, place the cylinder upside down and direct the gas flow away from the operator.

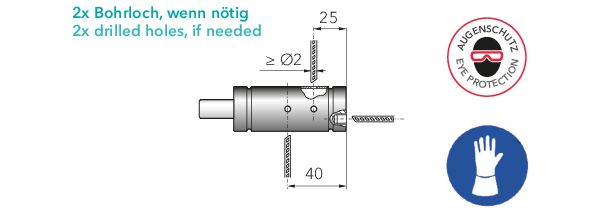

- If damage is suspected, the gas spring must be depressurised immediately while still in the installed position. This can be done by opening the valve or drilling a hole in the cylinder body until the gas has been discharged.

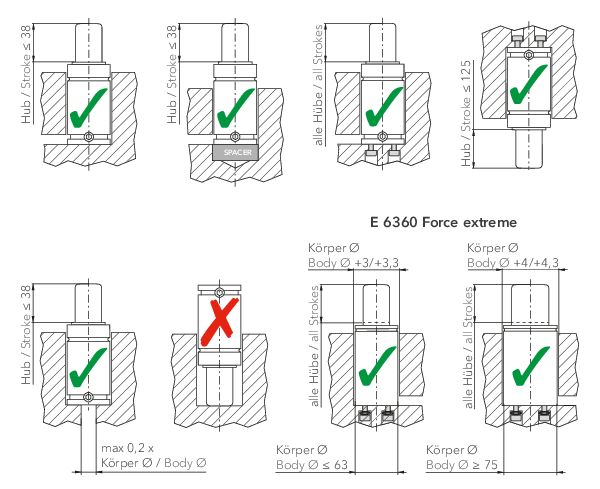

Installation options

Installation in a blind hole

Ensure that the contact surface is not interrupted or obstructed. After any modification to the die, check the gas spring‘s condition and its proper fit.

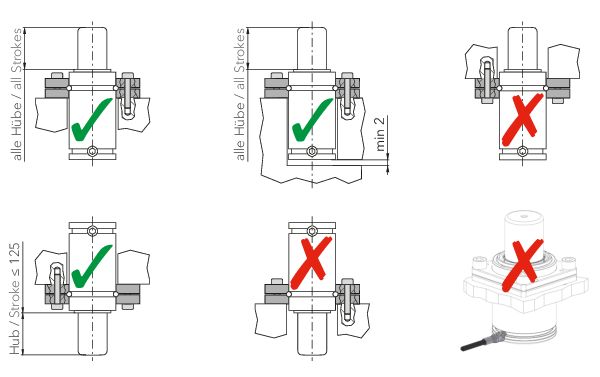

Top mount

Top mount with flange

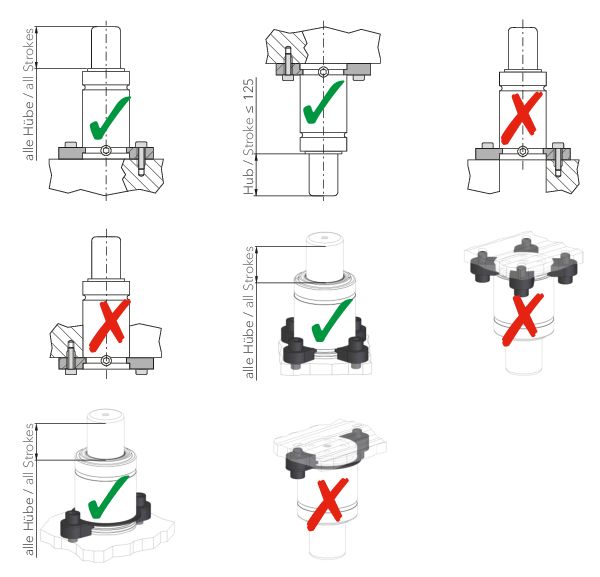

Base mount

Base mount with flange

Bottom mount

Use screws of a suitable length to use the full depth of the threaded hole on the cylinder.

Maintenance

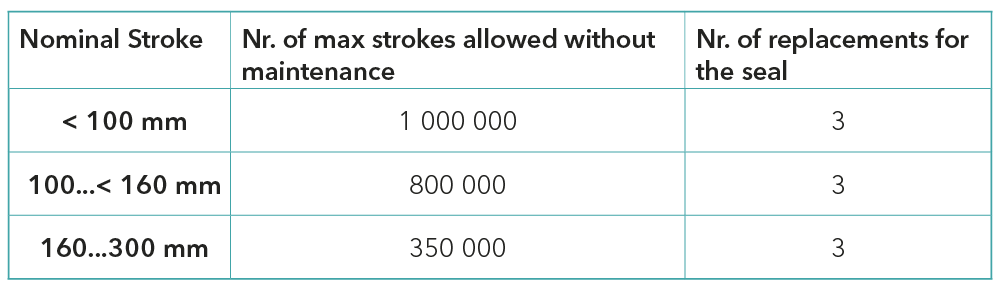

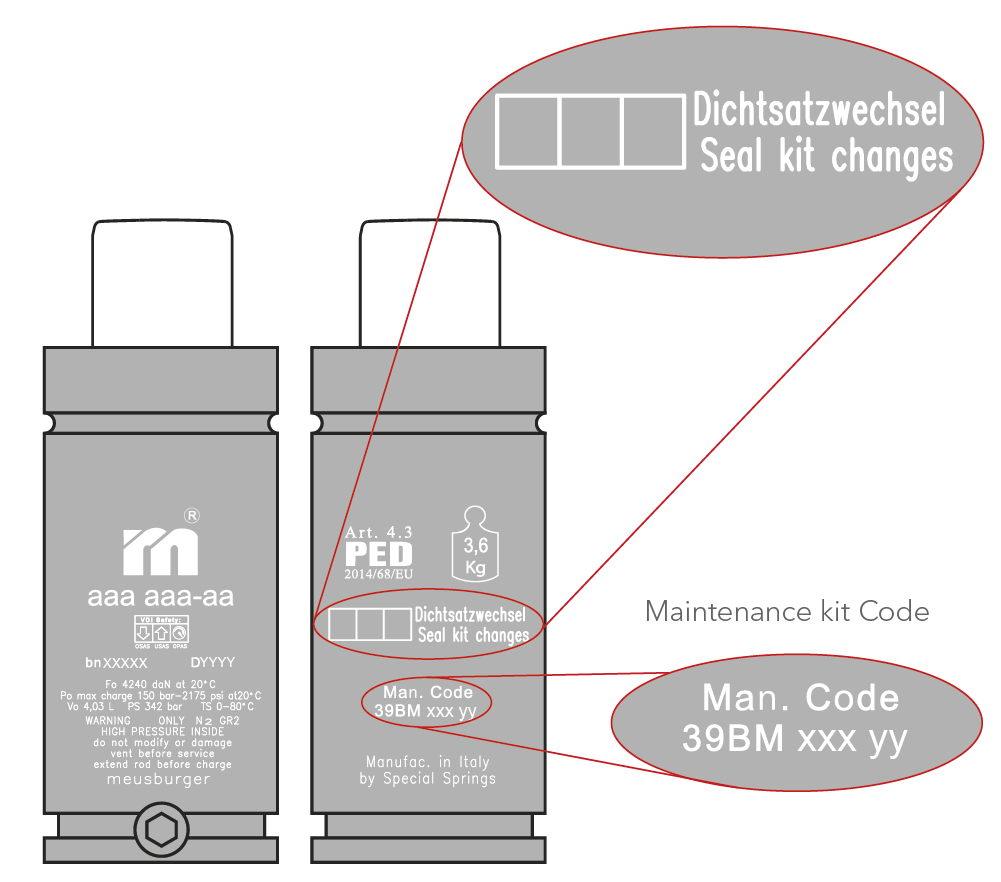

If the load limits stipulated by VDI 3003 (see chart) are exceeded, maintenance is required. The service can be carried out by Special Springs or independently on site by ordering the suitable maintenance kit that is delivered with a user manual. The maintenance kit code (Man. Code) is marked on the gas springs.

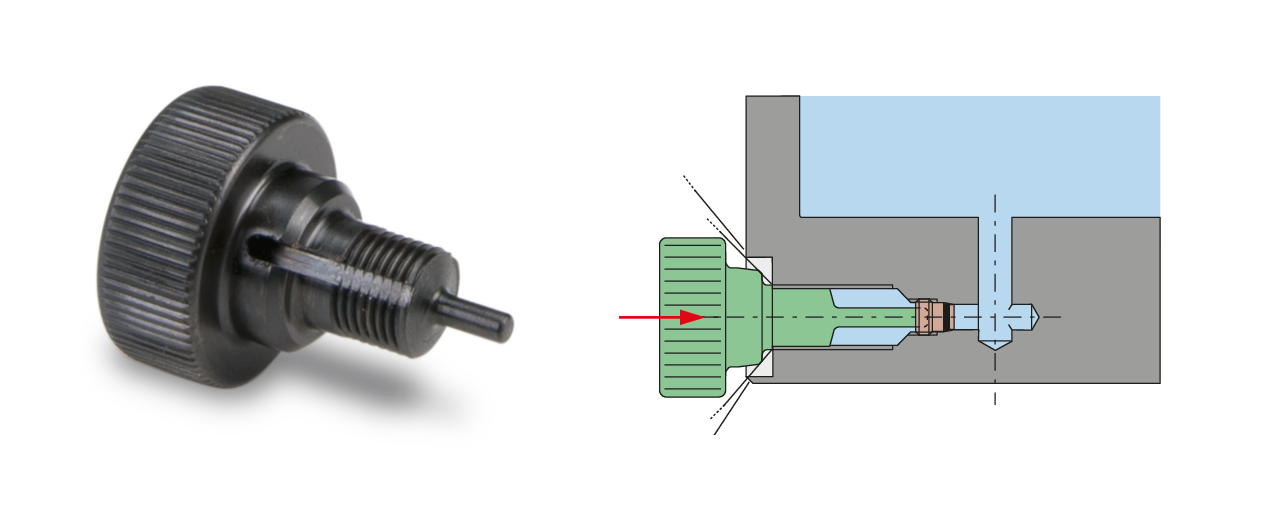

Pressure release device

For complete release of the gas spring’s pressure

Filling adapter

For refilling the gas spring

Tips for the correct storage of gas springs

- Storage in upright/horizontal position is no problem.

- Avoid storage with the piston rod pointing downwards.

- Storage in a dark place is not necessary, however we recommend avoiding direct sunlight.

- The gas spring can be stored for 1 to 2 years.

- The ambient temperature should be between 0° and 35°C.

- The best storage conditions are in closed rooms, with some ventilation, free of humidity and especially free of dust. Handle the gas springs carefully to avoid dents or scratches, especially on the piston rods.

- Avoid contact with corrosive chemicals and the vapours they emit.

- It is not necessary to lubricate the piston rod. Our gas springs are sufficiently lubricated before shipment.

- Please avoid cleaning the piston rod in order not to remove the lubricant and thus cause corrosion.

Företag

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2023 Meusburger

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]