What are the consequences of defective coolant hoses?

Coolant hoses and the associated couplers should be carefully selected and installed. Otherwise there may be time-consuming cleaning work, production interruptions or employee safety risks.

Possible causes of damage to the coolant hose

- Defective installation

- Poor coolant hose routing

- Coolant hoses rub on other components during the closing movement

- Kinking during crimping as the selected hoses are too short

- No or infrequent inspection

But how can you avoid damage and coolant hose leakage?

We have summarised the most important points for you here. You should pay attention to this both when planning a mould base and during the longer-term use of coolant hoses:

Right selection

The correct selection of coolant hose and suitable couplers is essential for fail-safe operation and personal safety. Special attention must be paid to the respective area of application and the permitted maximum temperatures.

Constructive layout

Whenever possible, you should consider the best possible layout of the coolant hose during the design phase. That way you can already avoid bending radii that are too small or chaffing hoses during the planning stage.

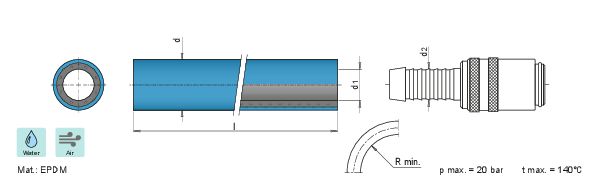

The value ‘R min.’ indicates the minimum radius that must be maintained for the optimal use of coolant hoses. You will find this information with every coolant hose in our range.

Professional installation

Leaks can often occur when the coupler and hose are connected. One possible cause for this is improper installation. Correct installation is essential for avoiding failures.

There are two different installation methods:

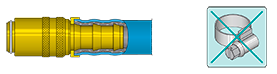

Installation without clips

For installation without clips, the quick-fit coupling system is ideal. Due to the shape of the quick-fit nozzles and the special construction of the quick-fit coolant hose, no additional clamps or ferrules are needed for installation.

Important: Installation without clips is only possible with quick-fit hose and the quick-fit coupling system. All other hoses and couplers must be additionally fixed.

For installing the hose on the nozzle, a little more force is needed. For this, we recommend the E 21990 hose assembly device.

Installation with clips

For normal nozzles, installation can be done either with hose clamps or ferrules.

The appropriate assembly tools are important for installation.

Regular inspection

The correct routing of the coolant hoses should be carefully checked before starting up the injection mould. In addition, regular inspection is important along the production process - we recommend a visual inspection after each mould set up or at least once a week.

The following points should be considered:

- Check hose for damage, cracks and abrasion

- Check older hoses for sufficient elasticity and replace if necessary

- Make sure the couplers are intact

- Check the range of movement of the hoses (look for signs of abrasion)

- Do not kink the hose in the nozzle area or in the bending radius of the hose

If there is a leak, it must be dealt with it as quickly as possible to avoid downtimes.

Our tip for quick repairs

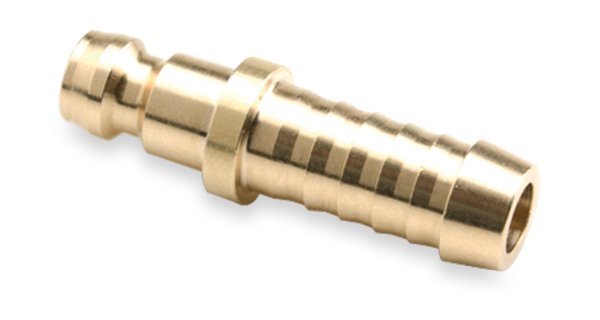

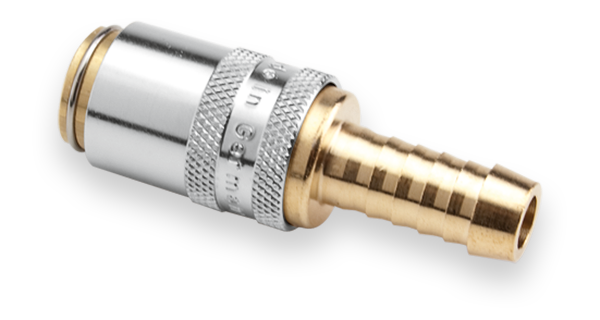

For quick repairs, Meusburger offers double hose nozzles (E 2069) or a fitting with hose nozzle (E 2068, E 20685) and a hose coupler (e.g. E 2200). That means that the existing hose can be quickly repaired on the spot.

Why is handling coolant hoses correctly so important?

It not only avoids production downtime, but also ensures operational safety and prevents injuries. In addition to the correct selection of parts and professional installation with the appropriate tools, the use of automatic locking safety couplers (e.g. E 22206) is recommended, especially at high temperatures.

Availability

If there are downtimes, it is important that production can be restarted quickly. If you don’t have the spare part, Meusburger delivers immediately from stock from the world’s largest standard parts warehouse.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]