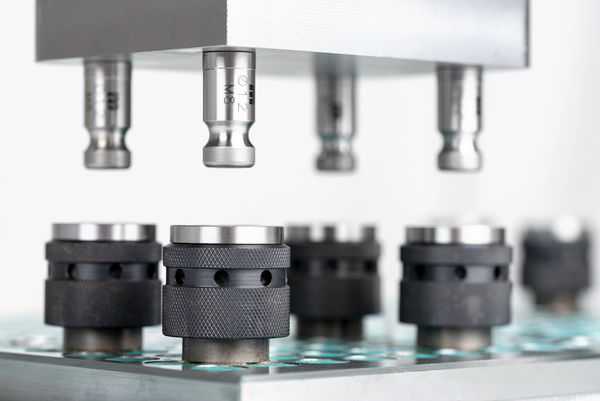

H 1082 clamping spigots

H 1082 clamping spigots are available with diameters of 11.6 mm and 12 mm.

- Clamping spigots with Ø 11.6 mm are used for NF inserts or workpieces, which are still subjected to a heat treatment process following machining. The fitting hole of the NF insert is subsequently expanded to Ø 12 mm, so that the clamping spigot can be used with Ø 12 mm for the clamping process of the rework.

- For workpieces without heat treatment, the Ø 12 mm clamping spigots can be used immediately.

Clamping with the H 1080 clamping supports offers the option of machining workpieces on all five sides without interfering contours. Due to centring at the zero point, repeatable accuracy of the clamping is in the µ range.

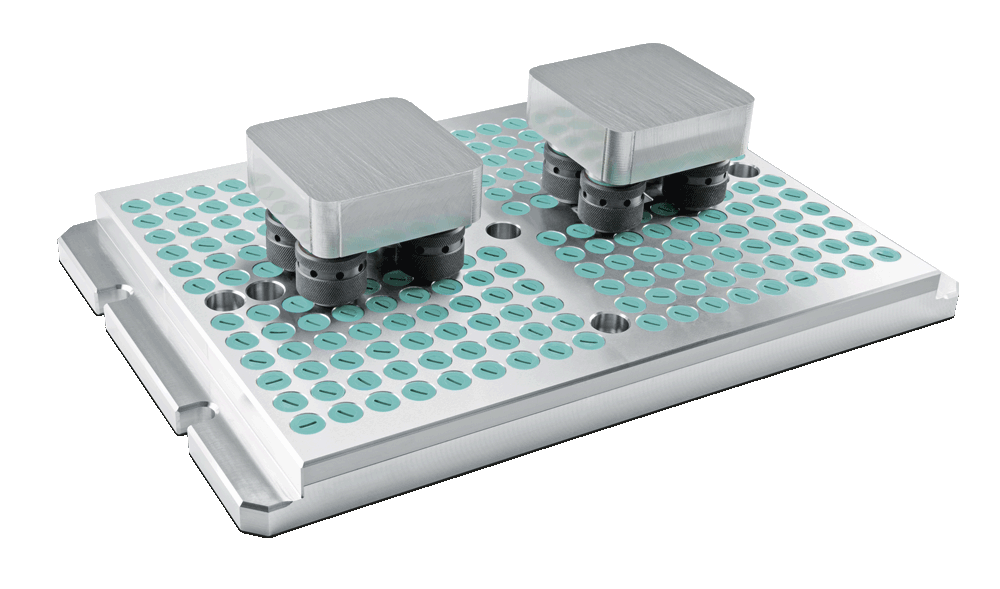

H 20100 clamping plate with 20 mm grid

Flexible item-based clamping of workpieces in a 20 mm hole grid is enabled by the H 20100 clamping plate combined with H 1080 clamping supports.

One-off positioning of the clamping plate on the machine table by means of high-precision alignment edge

Positioning and mounting of the H 1080 clamping supports in the 20 mm hole grid

- Reliable clamping of workpieces with repeatable accuracy with the specified fitting hole and threads into the clamping supports used

Lead times are shortened due to considerably reduced set-up times and programming is simplified by means of clamping without interfering contours.

Prepared plates for zero clamping system

With our clamping configurator you can quickly and easily order plates already equipped with holes for various zero clamping systems. Thanks to the preconfigured plates for the clamping system you are using (e.g. H 1082), nothing stands in the way of machining right away. A time-consuming changeover at the machine can also be avoided and costs for expensive machines and staff resources are saved.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]