Kontakti

Na voljo smo vam od ponedeljka do petka med 8:00 in 17:00 uro. Na tej povezavi najdete kontaktne osebe za svojo regijo.

Centrala Wolfurt

+43 5574 6706-0

Košarica {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} izdelek Zamenjaj košarico

Opomba

| Slika | izdelek | Kos | Cene po pozicijah | Skupna cena | Skupna cena s popustom | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Stranke

- Mould making

- Die making

- Strojegradnja in izdelava priprav

- Za-konstrukterje

- Brizganje

-

Izdelki

- Novi izdelki

- Ohišja za forme

-

štančna ogrodja

- SV-Standardna ohišja

- SP-Precizna ohišja

- SH-Ohišje z dvema vodilnima stebroma zadaj

- Plošče za SD-Ohišje z dvema vodilnima stebroma diagonalno

- SZ-Ohišje z dvema vodilnima stebroma na sredini

- Plates for SM-modular concept

- SB-OHIŠJA ZA PREOBLIKOVANJE PLOČEVINE

- Programska oprema Offline-trgovina

- P-Plošče

- N-PALICE STANDARDNE

- Plošče in palice

- Izdelava po naročilu

- E-Vgradni elementi

- Toplokanalna tehnika

- Regulacija toplokanalnih sistemov

- Vse za delavnico

- Podjetje

- Zaposlitev

- Servis

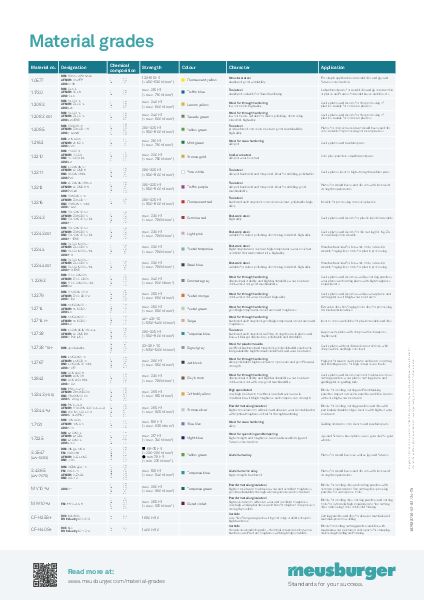

Naš izbran nabor omogoča za skoraj vsak primer uporabe ustrezen material.

1.1730 Tool steel

Designation

| DIN: | C 45 U |

| AFNOR: | XC 48 |

| UNI: | - |

| AISI: | 1045 |

Chemical composition:

| C | 0.45 |

| Si | 0.30 |

| Mn | 0.70 |

Strength:

max. 215 HB

(≈ 710 N/mm²)

Thermal conductivity at 20 °C:

50 W/m K

Character:

unalloyed tool steel with excellent machinability, good core toughness for minor applications; chilled cast steel, suitable for flame and inductive hardening

Application:

unhardened parts for mould, die and jig construction; plates and frames for mould bases and die sets

Treatment by

unusual:

Polishing, etching, EDM, nitriding, hard chroming

Heat treatment:

Soft annealing:

680 to 710 °C for about 2 to 5 hours

slow controlled cooling of 10 to 20 °C per hour to about 600 °C;

further cooling in air, max. 190 HB

Hardening:

800 to 830 °C

Quenching in oil/hot bath/air

Obtainable hardness: 58 HRC

hardening depth 3−5 mm

max. 15 mm through hardening thickness

Tempering:

Slow heating to tempering temperature immediately after hardening, to 180 to 300 °C depending on desired hardness

1 hour per 20 mm: min. 2 hours

Annealing graph:

Available in the web shop as:

P-Standard plates

P-Standard plates PR-Round plates

PR-Round plates R - Raw bars

R - Raw bars Standard bars

Standard bars NP-Precision bars

NP-Precision bars NR-Round bars

NR-Round bars NV-Square bars

NV-Square bars

Data sheet 1.1730

Podjetje

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]